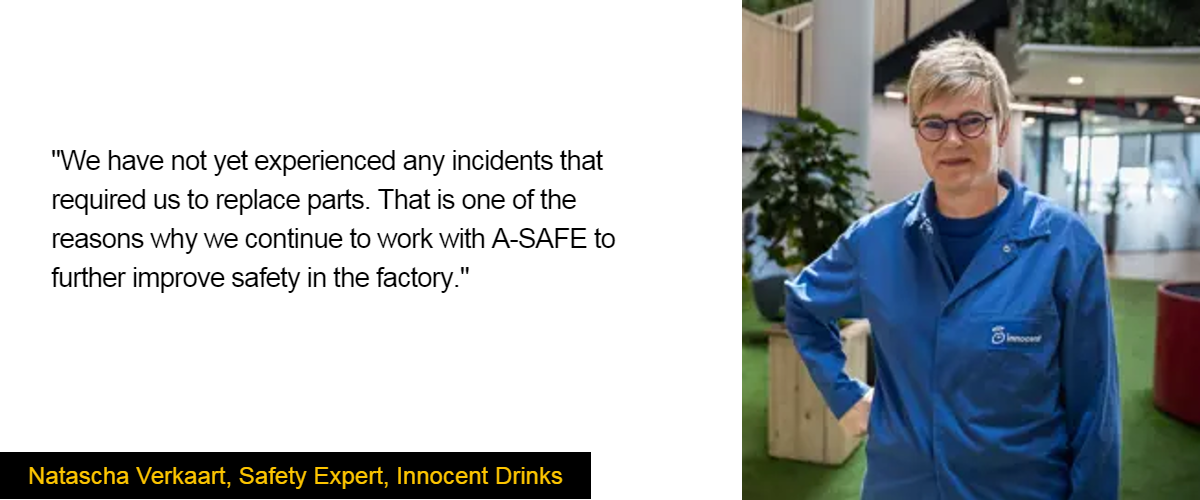

Case study Innocent Drinks

The company

Innocent Drinks was founded in 1999 by three graduate friends. Since that time, Innocent Drinks has gone on to sell more than two million smoothies per week, with drinks sold in 22 countries around the world. Now owned by Coca-Cola, has its own all-electric, fully renewable factory in Rotterdam, known as The Blender.

Sustainability is high on the agenda, with The Blender using its own solar panels along with renewable energy from a renewable tariff on the grid. Innocent Drink’s dedication to sustainability also extends to safety, with the supply of ingredients and packaging materials is largely done using automated guided vehicles (AGVs). These AGVs also assist with the removal of pallets containing end products to the wrapping machine and to the high-bay warehouse.

The problem

Although Innocent Drinks’ AGVs reduce the amount of forklift trucks needed on site, there are still some instances where forklifts were still needed and pedestrians had to be protected.

Having drawn up an extensive traffic plan, Innocent Drinks’ quality and maintenance departments tested two suppliers, with A-SAFE quickly coming out on top due to the stronger material, the hygienic seals and the overall appearance.

-

Protected a hyper-modern, sustainable warehouse in Rotterdam

-

A-SAFE solutions beat competitors in Innocent Drinks' testing

The A-SAFE solution

The A-SAFE collision protection can be found at various locations in the Blender. The installation for unloading fruit juices is protected against collisions with tankers, while collision protection protects drivers who walk forward or backward. In the warehouse where the other ingredients are stored, collision protection ensures that employees can operate their computers without having to fear for forklifts.

BackA-SAFE is a world leader in the production of safety barriers

Contact us and we will help you ensure safe operation, safe performance of work, protection of equipment, safety of employees and your property.