PAS 13: Understanding the regulations around safety barriers

Understanding PAS 13: The code of practice for safety barriers

What is PAS 13?

PAS stands for Publicly Available Specifications.

PAS 13 is the global code of practice for safety barrier installation and testing. It provides best practice guidance for correctly installing safety barriers throughout a facility. This includes guidelines on how best to layout barrier systems with an emphasis on pedestrian segregation, traffic management and the effective protection of machinery and buildings.

In additional to this, PAS 13 provides guidance on the most effective way to test safety barriers to ensure they are compliant and properly performance rated.

Who created the guidelines for safety barriers?

The PAS 13 document was created by the British Standards Institute (BSI). It was designed with help from an expert steering group which included The Health and Safety Executive and a group of leading brands from a range of industries and sectors. It was created with the intention of establishing a set of guidelines around the correct installation of safety barriers which could then become the industry standard.

PAS 13 also offers instructions on the correct way to test safety barriers to ensure they can provide the relevant protection needed on site.

A-SAFE was the technical author of PAS 13 and it also sponsored the document.

Who are the BSI?

The BSI are the world’s first national standards body. They were appointment by the UK Government and hold a Royal Charter to develop globally recognised standards that encourage people and organisations to operate more effectively.

Who was part of the PAS 13 expert steering group?

The BSI worked with a range of blue-chip companies from a variety of sectors around the world to develop the PAS 13 code of practice. The partners included:

- Jaguar / Land Rover

- DHL

- TÜV Nord

- Nestle

- MARS

- RIBA Enterprises

The steering group was able to identify the relevant needs for industries including manufacturing, distribution and food and drink processing.

Who is TÜV Nord?

TÜV Nord is one of the worlds’ leading certification and inspection bodies. Their remit covers a wide range of industries and technologies where they provide independent expert inspections. In relation to PAS 13, TÜV Nord was one of the members of the steering group, while also providing accreditation to PAS 13-compliant safety barriers.

How can I purchase PAS 13?

The PAS 13 document can be purchased from the BSI website or alternatively, you can purchase it with an exclusive discount from the A-SAFE website.

As a PAS 13-compliant safety barrier manufacturers, A-SAFE can provide effective advice and support for your site safety needs. Contact us to learn more.

Safety Barrier regulations: PAS 13, Traffic Management and accident reduction

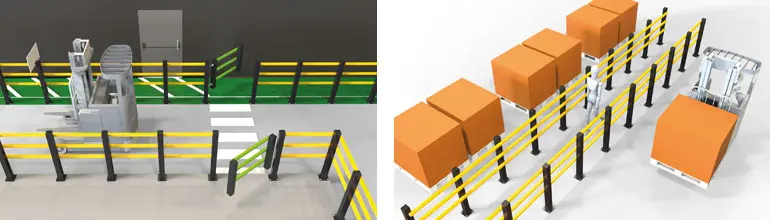

The remit for PAS 13 was to cover two specific areas of safety barrier application. The first was the correct configuration and installation of safety barriers, which considered the use of safety barriers in traffic management and pedestrian protection.

Crossing points

In busy facilities, crossing points can be accident hotspots. PAS 13 provides detailed information on how best to configure crossing points to minimise the potential for accidents, through a combination of traffic flow management and pedestrian segregation. The intention is to encourage both pedestrians and drivers to pause before approaching a crossing point and consider the potential risks.

PAS 13 outlines ways to improve safety at crossing points using:

- Overhead walkways where possible

- Crossgate configurations

- Offset doorways to slow pedestrians entering and crossing a facility

- The use of pull gates to slow pedestrians

- The application of crossing gates that don’t hinder evacuations during an emergency

Traffic management

As part of its remit, PAS 13 tackles ways to effectively manage traffic through busy factories and warehouses. The code of practice details ways to minimise the risks that come with site vehicles which include:

- Planning vehicle and pedestrian routes in conjunction with each other

- Segregating pedestrians

- Working within one-way systems

- Using funnel systems to draw vehicles away from vulnerable areas of a site

In addition to this, PAS 13 ensures that vehicles routes

- Are the appropriate width for vehicles

- Avoid slopes and sharp blind bends

- Are properly signposted

- Are free from obstructions and well-maintained

Handrails

In order to ensure that pedestrians are properly supported as they navigate a busy facility, PAS 13 outlines the practical application of effective handrails. The correct use of handrails and balustrades can make the different between keeping your workforce safe or not. PAS 13 outlines:

- The benefits of a higher fulcrum point to prevent people falling over the side

- The optimum strength of a pedestrian barrier (to support two adults leaning)

- The benefit of smooth surface areas and no sharp edges to reduce injury

Safety barrier heights

PAS 13 outlines the important of ensuring that barrier heights match the impact zones and types of vehicles in operation. In order to be completely effective, barriers must provide protection that is at the appropriate height. This includes:

- Considering heights of vehicle impact zones

- Ensuring barriers are tested to real life simulations

- Effective ground protection must be installed to defend from vehicle forks

- Key infrastructure and machinery should have appropriate protection

Lines of vision

The installation of safety barriers and bollards are an effective way to prevent unwanted impacts to machinery, infrastructure and workers, however you must consider lines of vision to ensure these measures are properly observed. PAS 13 addresses the need to consider lines of vision for both pedestrians and those driving site vehicles, which includes:

- Factoring lines of vision into the planning of safety systems

- Considering the POV of drivers and pedestrians

- Creating clear visual cues for drivers of articulated vehicles

Pedestrian segregation

PAS 13 outlines the importance of using safety barriers to effectively segregate pedestrians from vehicle routes. The code of practice states that safety barriers are needed between walkways and vehicle routes if they are closer than 1 meter and not separated by a raised kerb. Pedestrian barriers are not needed in areas where hand-operated vehicles, such as pallet trucks, are being operated.

The code of practice also addresses:

- Planning pedestrian routes around desire lines where possible

- The appropriate width for walkways

- Accounting for the deflection zone of a barrier to protect pedestrians

- The use of raised kerbs to prevent vehicles from straying

- Safe zones to adjust vision between areas of differing light levels

- The use of proper signage and colour demarcation

- Offsetting doorways from crossings and using gates to slow down pedestrians

Buildings and equipment

In additional to protecting a workforce, it is important to shield valuable equipment and structures on site. From walls, doorframes and columns to machinery and electrical equipment, there are many vulnerable spots in a factory or warehouse. It is important to identify these risks early. PAS 13 provides guidelines on effective protection. It provides advice on:

- Ground level protection for structures from vehicle forks

- Using highly visible bollards and barriers for protection

- Using signposts and floor markings to create visual cues

- Employing funnel designed entrances to direct vehicles away from vulnerable structures

- Softening blind corners on vehicles routes

- Allowing space for barrier deflection zones

Standard colour demarcation

For safety systems to be effective, they must be clearly visible. A barriers’ first function is to be seen in a busy or crowded facility. The visibility of safety barriers and bollards can be achieved through repainting or using systems with self-coloured designs. PAS 13 outlines the best way to utilise globally recognised standard colour demarcation, including:

- Yellow and black to signify caution

- Red and white to signify a warning

- Green to signify pedestrian safe zones and exits

Whatever you reason for purchasing safety barriers, from pedestrian segregation to effective traffic management, we can help. We also have a range of additional safety products to ensure staff and machinery are properly protected on site.

Safety Barrier Testing Guidelines: Standardising impact ratings

In addition to aiding site safety through the application of safety barriers, PAS 13 was created with the intent to standardise the testing of safety barriers. This was to ensure that any barriers claiming to be PAS 13-compliant have met the rules of effective testing outlined in the code of practice.

Why is it important to standardise testing?

PAS 13 was designed to bring more consistency to the testing of safety barriers. By standardising elements of the testing process, customers can be sure that PAS 13-compliant barriers can withstand the forces specified in their impact ratings.

What is an impact rating?

Impact ratings are the figures specified by manufacturers to show the force a barrier can withstand in an impact. They are often measured in Joules and are a result of multiplying the mass of a vehicle by its velocity, while factoring in the angle of impact.

These ratings allow customers to understand how much force a barrier can withstand. When the data used to capture these ratings is not in line with PAS 13, it can be hard to know if the information is truly accurate. This could put machinery and infrastructure at risk, or worse, mean that people are not effectively protected from vehicle impacts.

Can I trust the claims of barriers that are not PAS 13 compliant?

Every manufacturer will have different specifications and claims about what their barrier can withstand, but it’s important to be aware of how that data has been captured.

PAS 13-compliant barriers must state impact ratings that include a 5% safety factor. This means, the impact rating stated by the supplier is 5% lower than the force it was tested to. This leeway guarantees that the barrier is more than capable of withstanding the stated impact force.

Some manufacturers offer impact ratings that reflect the force used to destroy the barrier during testing. While the impact rating may be higher than a PAS 13-compliant product, the likelihood is that a barrier would fail when impacted with this force, rendering it useless and putting the people or objects behind the barrier at risk.

What other factors can affect a barrier supplier’s impact rating?

There are many factors that can affect a barrier impact rating. If a vehicle is going faster than the recommended speed limit or carrying more than the specified load weight, barriers can fail when impacted. Therefore, standardising the testing process is crucial. It ensures workplaces can follow the guidelines effectively to minimise the risks in the event of a collision.

Another factor that can affect the success of a safety barrier is proper barrier heights. Some manufacturers may suggest that low-level barriers can stop site vehicles without specifying what height they should be. In some cases, if the barrier is too low, a vehicle going fast enough can drive over the barrier rather than being stopped.

Testing safety barriers to PAS 13 standards

In order to ensure safety barriers are compliant, tests must use:

The correct equipment

If you are testing safety barriers, it’s important to ensure you have the correct equipment. PAS 13 outlines the specific equipment needed to perform compliant safety barrier tests. These include:

- A minimum of 2 barriers for each test

- A fixture system to anchor the barrier to the ground

- Line marking material for the test and deflection areas

- A high-speed camera

- A standard camera for visual inspections

Compliant vehicles

If you are testing safety barriers to ensure they can withstand the stated weight and speed of a vehicle, it is best to ensure your testing area is compliant.

Test areas must include a range of specifications, including:

- A robust sled with resistance-free wheels

- No obstructions between the sled and the barriers

- A solid ramp structure with an inclined plane

- Parallel ramp tracks or rails to guide the sled

- A winch to pull the sled to the desired height

- A speed trap consisting of two mats or lasers to measure the vehicle velocity on impact

Properly prepared impact areas

In order to achieve the most accurate results, it is important to set up the impact area properly. Set up includes:

- Preparing the bumper or forklift striker

- Attaching the sled to the winch and fitting the appropriate weights

- The sled much be guided by rails to prevent scraping or diversion

- The use of a speed trap to verify the vehicle velocity

- High speed camera to capture the test for further analysis

- Test barrier must be secure and include marked lines to measure deflection

Procedures to follow

Once the vehicle and equipment has been set up to the guidelines, it is important to follow the proper procedures.

The full test procedure must be applied to these barrier components:

- The end post

- The rail centre

- The mid post

When testing:

- The testing of bollards must be performed at a height of 200-500mm

- Each competent must be tested twice with new barriers for each new test

- Test the barrier at the highest and lowest temperatures at which it could be used

- Quarantine the test area to keep pedestrians safe

- Impact ratings must use a safety factor of 5% - lower than the energy recorded in testing

- Record the results in the test report

What does a full test look like?

Once your vehicle and equipment are ready and the correct procedures are being followed, you are ready to perform an impact test. The below video shows how a proper test should look.

Recording and reporting your results

The data required to be collected during a test must then be compiled into a standardised report. The report includes details of the following information:

- Test method

- Description of barrier

- Environment tempo and humidity

- Mass and striker used

- Kinetic energy being applied

The data captured during an impact test includes:

- Whether the barrier or bollard has passed of failed the test

- The deflection of the barrier during impact

- The force applied to the fixings

- Any damage sustained by the barrier or bollard

Examples of test documents can be found in the PAS 13 Code of Practice.

Passing or failing a test

There are four criteria by which a barrier can pass or fail an impact test:

- If the barrier does not stop the test vehicle or striker

- If the striker or vehicle breaches the test barrier

- If the barrier is rendered structurally unsound and damaged beyond performance

- If the fixings fail by being pulled out of the floor (possibly because the tested force is higher than the manufacturers’ rated force)

A-SAFE barriers already meet the strict standards outlined in the PAS 13 testing guidelines, so contact us to find out how they can help you protect your facility from unwanted vehicle collisions.

PAS 13: Summary

At A-SAFE, we are committed to improving the standards of safety at workplaces around the world. That’s why we helped to drive the PAS 13 code of practice through – to ensure those who invest in safety barriers feel confident in their choice.

If you would like to purchase PAS 13, you can buy it from the BSI website or buy it with an exclusive discount from A-SAFE on our website.

BackA-SAFE is a world leader in the production of safety barriers

Contact us and we will help you ensure safe operation, safe performance of work, protection of equipment, safety of employees and your property.